Airlines’ belief in the Airbus superjumbo is faltering

ONE of the most insightful responses to a Gulliver article was below the line of a post about air turbulence, and how flyers often overestimate its effects. The mysterious “guest-nialmnj” wrote:

No amount of fancy aeronautical engineering calculations can change the fact that the notion of any vehicle of such vast weight and size actually flying is patently absurd; planes are clearly kept aloft by sorcery and the collective (if misguided) belief of their passengers. This so-called turbulence arises when the faith of some of those passengers falters for a moment.

Gulliver lives just a few miles

@ArlinesTechnologies

Gulliver lives just a few miles east of Heathrow on the flight path. He often sits in his garden and watches A380 jumbos fly overhead, less than a minute into their enchanted journeys to the Middle East or Asia. He knows guest-nialmnj to be a sage. Watching beasts as mighty as Airbus’s double-deck leviathan take to the air is enough to make one wonder at the laws of physics.

Gulliver lives just a few miles east of Heathrow on the flight path. He often sits in his garden and watches A380 jumbos fly overhead, less than a minute into their enchanted journeys to the Middle East or Asia. He knows guest-nialmnj to be a sage. Watching beasts as mighty as Airbus’s double-deck leviathan take to the air is enough to make one wonder at the laws of physics.

Alas, such a magnificent sight may well become less common in the future. Not because the collective belief of the passengers has failed, but because that of airlines has.

On 14th September, Singapore Airlines (SIA) announced that it would not be renewing the lease on five of its A380s when the ten-year contract expires next year. It said that it has not made a decision on its remaining four leased Airbus jumbos, though there is a good chance that they, too, will be consigned to SIA’s history.

Design complexity simplifiedwith CNC machining technology

Design complexity simplifiedwith CNC machining technology

How complex gears are engraved with extreme precision! Complex wooden designs, which are too intricate to understand! How man to achieve that was, was it mere manual work or advanced knowledge; was it a supernatural occurrence? An ordinary individual may ask these usual questions on coming across complex engineering designs. What is your thought?

In the late 1970s, man invented a machine technology, which would allow complex designs to be made by machines automatically, with minimal manpower, and proper timing. This technology has indeed advanced significantly in the 21st century, thus making it possible to design and develop complex components, which would have proved a nightmare without current technology. Let us look with the intent on the actual Robotic machine technology.

1.

Computer Numerical

Control (CNC) Machining

CNC machining is the use of a computer with a unique Computer software program composed of a numerical machine language, designed to control the movement of the machine components with extreme precision while performing a task. Especially applied on lathes, routers, mills and grinders.

2.

How

it works

A CAD drawing of either two dimensions or three dimensions is created and a programming code that the CNC machining will understand is uploaded, then it’s tested on the machine to ensure that there are no errors. This test is of extreme importance since it checks on speed and position because having a fault in operation could result in machine damage or even injuries to the operator.

3.

Significance of

CNC Machining

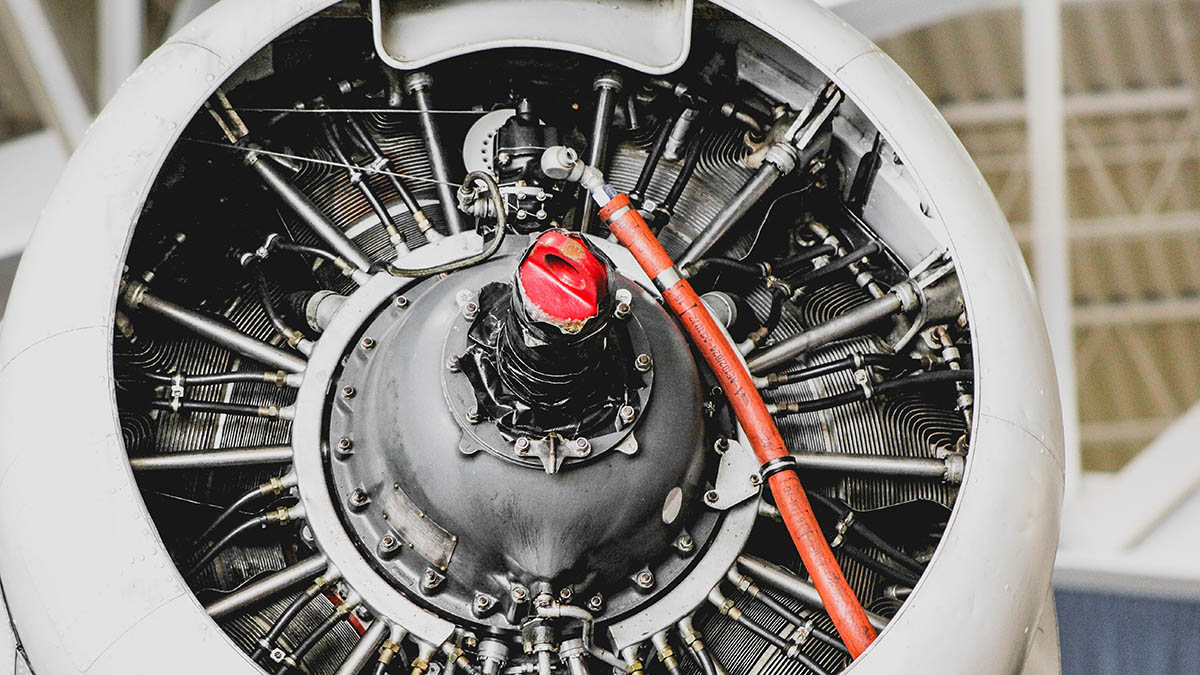

The CNC machining automated control ensures extreme precision, with high-level accuracy, especially on repetitive tasks. Indeed the CNC numeric program is unambiguous, meaning that errors in design are outdated, and the ideology of safety and time management is well accommodated in this mechanism. Work is done with minimal manpower as all is automated through the CNC software program. Accuracy and the high degree of precision in cutting internal threads. Observe the picture. (Done by lathe machine using CNC machining)

4.

What are the basic requirements

to acquire the CNC skills?

I am sure you would like to have an idea of the function and operation of the CNC machining technology. Indeed all you need is a background and in mathematical skills, industrial arts, mechanical drafting and computer skills.

5.

Where do you

acquire CNC Training?

CNC machining skills can be acquired through training in the CNC numeric programming allowing you to gain acquaintance to machine operation protocol. There are various technical institutes to link up with, such as the Lincoln’s CNC machining and manufacturing technology program. The Lincoln College of Technology in Indianapolis in collaboration with Lincoln Technical institute Mahwah, NJ, and Lincoln College of Technology in Grand Prairie TX.

Here you will be able to learn and gain the most needed skills and experience in modern manufacturing machines with most advanced technology, therefore, graduating with all the necessary qualifications needed as the machine operator or a setup technician.

How did you get your idea or concept for the business?

This is an aside post.

This week the class will focus on the work of Ansel Adams. If you haven’t already, you’ll need to purchase Ansel Adams: An Autobiography (available at the school bookstore) and read chapters 1 through 4. In particular, I want you to focus on this section from chapter 2:

Adams also came to understand how important it was that his carefully crafted photos were reproduced to best effect. At Bender’s invitation, he joined the prestigious Roxburghe Club, an association devoted to fine printing and high standards in book arts. He learned much about printing techniques, inks, design, and layout which he later applied to other projects. [1]Some of Adams’ success can be attributed to how successfully he replicated his work through printing. This week we’ll be learning about his print techniques and making some prints of our own.

Typi non habent claritatem insitam; est usus legentis in iis qui facit eorum claritatem. Investigationes demonstraverunt lectores legere me lius quod ii legunt saepius. Claritas est etiam processus dynamicus, qui sequitur mutationem consuetudium lectorum. Mirum est notare quam littera gothica, quam nunc putamus parum claram, anteposuerit litterarum formas humanitatis per seacula quarta decima et quinta decima.

What is 3D printing and how does it work?

Golden Gate Bridge

Strauss was chief engineer in charge of overall design and construction of the bridge project.However, because he had little understanding or experience with cable-suspension designs, responsibility for much of the engineering and architecture fell on other experts.

Strauss’s initial design proposal (two double cantilever spans linked by a central suspension segment) was unacceptable from a visual standpoint. The final graceful suspension design was conceived and championed by Leon Moisseiff, the engineer of the Manhattan Bridge in New York City.

Irving Morrow, a relatively unknown residential architect, designed the overall shape of the bridge towers, the lighting scheme, and Art Deco elements, such as the tower decorations, streetlights, railing, and walkways. The famous International Orange color was originally used as a sealant for the bridge. The US Navy had wanted it to be painted with black and yellow stripes to ensure visibility by passing ships.

Senior engineer Charles Alton Ellis, collaborating remotely with Moisseiff, was the principal engineer of the project. Moisseiff produced the basic structural design, introducing his “deflection theory” by which a thin, flexible roadway would flex in the wind, greatly reducing stress by transmitting forces via suspension cables to the bridge towers. Although the Golden Gate Bridge design has proved sound, a later Moisseiff design, the original Tacoma Narrows Bridge, collapsed in a strong windstorm soon after it was completed, because of an unexpected aeroelastic flutter. Ellis was also tasked with designing a “bridge within a bridge” in the southern abutment, to avoid the need to demolish Fort Point, a pre-Civil War masonry fortification viewed, even then, as worthy of historic preservation. He penned a graceful steel arch spanning the fort and carrying the roadway to the bridge’s southern anchorage.

Below Golden Gate Bridge

Ellis was a Greek scholar and mathematician who at one time was a University of Illinois professor of engineering despite having no engineering degree. He eventually earned a degree in civil engineering from the University of Illinois prior to designing the Golden Gate Bridge and spent the last twelve years of his career as a professor at Purdue University. He became an expert in structural design, writing the standard textbook of the time. Ellis did much of the technical and theoretical work that built the bridge, but he received none of the credit in his lifetime. In November 1931, Strauss fired Ellis and replaced him with a former subordinate, Clifford Paine, ostensibly for wasting too much money sending telegrams back and forth to Moisseiff. Ellis, obsessed with the project and unable to find work elsewhere during the Depression, continued working 70 hours per week on an unpaid basis, eventually turning in ten volumes of hand calculations.

With an eye toward self-promotion and posterity, Strauss downplayed the contributions of his collaborators who, despite receiving little recognition or compensation, are largely responsible for the final form of the bridge. He succeeded in having himself credited as the person most responsible for the design and vision of the bridge. Only much later were the contributions of the others on the design team properly appreciated. In May 2007, the Golden Gate Bridge District issued a formal report on 70 years of stewardship of the famous bridge and decided to give Ellis major credit for the design of the bridge.

What kind of music, the workers listen to when building bridges ?

Mario Peshev piano.

You need to listen to something that focuses you. It needs to keep you motivated, as well as keeping you calm and collected. Ready for business.